Designer

Snowflakes - Part One

... First attempts ... |

|

While

studying the physics of how snow crystals form and grow, I also became interested in the

art of growing synthetic snowflakes. These are basically identical to what falls

from the sky, except they are made in the lab under controlled conditions. I also

like to call them designer snowflakes, since in principle one could design

whatever shape one wanted ... within the bounds of the crystal-growing physics, of course.

Why make designer snowflakes? Partly

it's the challenge of reproducing what's found in nature, and perhaps doing better than

nature. There's also a sound scientific motivation for making designer snowflakes,

since often the best way to understand a phenomenon is to try and reproduce it in the lab.

One might even learn something interesting about crystal growth along the way.

|

| The

Art of Growing Snowflakes |

Start with a Diffusion Chamber Start with a Diffusion Chamber

There are many ways to grow snowflakes (see the Designer's Page),

but my favorite starts with something called a vapor diffusion chamber.

This is essentially nothing more than an insulated box that is kept cold on the bottom

(say -40C) and hot on the top (say +40C). A source of water is placed at the top,

and water vapor diffuses down through the box, producing supersaturated air. The

cold, supersatured air at the center of the chamber is ideal for growing ice crystals.

Our first diffusion chamber was the rather simple affair shown at right --

mostly made of plexiglas and styrofoam. I worked with Caltech undergraduate Victoria

Tanusheva to make our first designer snowflakes in this apparatus in the summer of

1997.

|

| Electric

Needles |

While working with this diffusion chamber, we rediscovered a

wonderful technique for growing synthetic snow crystals that was first published in 1963

by meteorologist Basil Mason and collaborators [1]. One starts by putting a wire

into the diffusion chamber from below, so that small ice crystals begin growing on the

wire's tip. Then apply a high voltage to the wire, say +2000 volts, and voila

-- slender ice needles begin growing from the wire. While working with this diffusion chamber, we rediscovered a

wonderful technique for growing synthetic snow crystals that was first published in 1963

by meteorologist Basil Mason and collaborators [1]. One starts by putting a wire

into the diffusion chamber from below, so that small ice crystals begin growing on the

wire's tip. Then apply a high voltage to the wire, say +2000 volts, and voila

-- slender ice needles begin growing from the wire.

The great thing about electric needles is that you can grow snow stars on

their ends. The picture at right shows five electric needles growing out from our

initial ice-covered wire, and each needle is topped with a snow star. The right

image is a negative close-up of the same cluster of needles (from a different viewpoint);

the diameter of the snow star is 2.4 mm.

In addition to the pretty pictures, we also spent a fair bit of time puzzling

over exactly how the electric needles grow, which we showed was because of an electrically

induced growth instability [2]. |

| Snow

Stars |

These two pictures show a well-formed snow star

growing at the end of a long electric needle crystal. The left image is after about

10 minutes of growth, the right image about 5 minutes later. The diameter of the

star in the right-hand image is roughly 2.5 mm. The temperature of the crystal was

varied with time to change the crystal growth morphology, giving the crystal its unique

form. These two pictures show a well-formed snow star

growing at the end of a long electric needle crystal. The left image is after about

10 minutes of growth, the right image about 5 minutes later. The diameter of the

star in the right-hand image is roughly 2.5 mm. The temperature of the crystal was

varied with time to change the crystal growth morphology, giving the crystal its unique

form.

|

|

Here is another large dendritic star; the right-hand image shows the star after the

background crystals were carefully removed. |

Two shots of a cluster of numerous snow stars growing on electric needles. |

Moviemaking Moviemaking

This time series of pictures shows the growth of a large star (final diameter

about 4.5 mm). First the wire was placed at a position in the chamber where the

temperature was -5C and an electric needle was grown (see Electric

Growth). Then the voltage was turned off and the needle moved to -15C, where a

stellar dendrite formed. Then the temperature was cycled between roughly -15 C,

which gave rapidly growing dendritic spikes, and -12 C, which produced more-slowly growing

sectored plates. Each of the sub-images is shown at the same scale.

See Snowflake Movies

for some movie clips of growing snowflakes. |

|

Here are some random dendrites grown in our diffusion

chamber, which form at a temperature of around -15 C. Note the appearance of

sectored plates in some of the images, which results from lower supersaturations. Here are some random dendrites grown in our diffusion

chamber, which form at a temperature of around -15 C. Note the appearance of

sectored plates in some of the images, which results from lower supersaturations. |

|

Some typical needle-like crystals which grow around -5C. |

| The

Hardware |

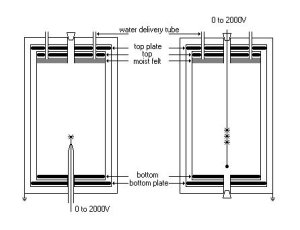

This shows a

schematic view of the vapor diffusion chamber. Dimensions of the inner box are

15x15x32 cm. The bottom plate was cooled to as low as -50 C while the top plate was

heated to as high as 40C. The temperature gradient created a stable environment

since warm air floats on top of cold air. Water vapor diffused downward to make

supersaturated air in the center of the chamber. This shows a

schematic view of the vapor diffusion chamber. Dimensions of the inner box are

15x15x32 cm. The bottom plate was cooled to as low as -50 C while the top plate was

heated to as high as 40C. The temperature gradient created a stable environment

since warm air floats on top of cold air. Water vapor diffused downward to make

supersaturated air in the center of the chamber.

Crystals were grown either on the tip of a tungsten wire (left) or along a

nylon string (right). The three layers of chamber walls were made from acrylic

sheet, with styrofoam insulation between layers. |

Imaging was done from the side, using a

standard video camera attached to one eye of a stereo microscope. Images were

digitized using a Snappy frame grabber, with SnapCap software for time-lapse

imaging. (This was before the era of cheap digital cameras!) The images were

all digitized at a resolution of 640x480 pixel resolution, and typically have a scale of

10 microns/pixel. . Imaging was done from the side, using a

standard video camera attached to one eye of a stereo microscope. Images were

digitized using a Snappy frame grabber, with SnapCap software for time-lapse

imaging. (This was before the era of cheap digital cameras!) The images were

all digitized at a resolution of 640x480 pixel resolution, and typically have a scale of

10 microns/pixel. . |

And finally we have a picture of Vicky Tanusheva at the helm. And finally we have a picture of Vicky Tanusheva at the helm. |

|

| [1] J. T. Bartlett, A. P. van den Heuval, B. J.

Mason, Z. angue. Math. Phys. 14, 509 (1963). [2] "Electrically Induced Morphological Instabilities in Free Dendrite

Growth," K. G. Libbrecht and V. M. Tanusheva, Phys. Rev. Lett. 81,

176 (1998). (see our published

papers) |