Prof. William L. Johnson Research Interests

Professor Johnson's group does research on non-equilibrium and metastable materials. During the past decade, they have developed unusual metallic alloys which fail to crystallize during solidification at low cooling rates, thus forming "bulk" glasses. Research on the liquid alloys includes fundamental studies of rheology, atomic diffusion, crystallization kinetics, liquid/liquid phase separation, and the glass transition. Research on the solid "glassy" materials includes studies of elastic properties, and mechanisms of deformation, flow, and fracture. The group has developed composite materials which employ a metallic glass matrix to achieve unusual combinations of properties for structural engineering applications.

Prof. Johnson's research group makes fundamental studies of materials far from equilibrium. This includes synthesis, processing, and characterization of such materials. Materials of particular interest include:

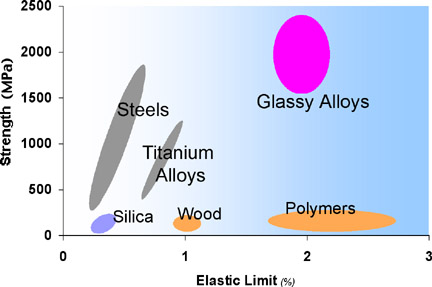

Typical strengths and elastic limits for various materials. Metallic glasses are unique.

Conventional metallic materials have a crystalline structure consisting of single crystal grains of varying size arranged in a microstructure. Such structures are produced by the nucleation and growth of crystalline phases from the molten alloy during solidification. By contrast, certain oxide mixtures (e.g. silicate glasses), have such sluggish crystal nucleation and growth kinetics, that the liquid can be readily undercooled far below the melting point of crystals (e.g. a quartz crystal). At deep undercooling, these oxide melts undergo a "glass transition" and freeze as vitreous solids. Professor Johnson's group have developed multicomponent metal alloys which vitrify with the same ease as observed in silicate melts. These bulk metallic glasses (BMG's) have unusual properties. They are typically much stronger than crystalline metal counterparts (by factors of 2 or 3), are quite tough (much more so than ceramics), and have very high strain limits for Hookean elasticity (see figure above). A new class of engineering materials, BMG's offer an opportunity to revolutionize the field of structural materials with combinations of strength, ductility, toughness, and processability outside the envelope achievable using current technology.

On the scientific side, the development of BMG alloys has made possible detailed fundmental studies of the undercooled liquid state and the glass transition in metallic systems. Quite unexpectedly, it has been found that the liquid BMG alloys exhibit atomic transport and rheological characteristics very different from simple metals and previously thought to be unique to oxide/silicate materials. Further, the traditional theory of crystal nucleation has been found to be inapplicable in these materials and the development of new theory based on chemical kinetics in the melt is in progress.

Professor Johnson is currently heading a multi-university DoD project to develop structural amorphous metal for use in such diverse areas as aircraft, autos, sports products, and medical implants. The project includes collaborations with several companies (e.g. Boeing and General Motors).

Prof. Bill Johnson shows a golf club head cast from bulk metallic glass. A large plate of metallic glass is leaning against the golf cart in front of its rear tire. Keck Laboratory is to the left.

A bar of some of the first bulk metallic glass.

Large casting of bulk metallic glass, with smaller castings of golf club heads.

Past work included studies of the crystal to glass transformations, mechanically alloys, nanophase materials, ion solid interactions, and materials processing by rapid solidification methods.

Recent work focuses on the study of "bulk" metallic glass forming alloys. The group has developed several families of metallic alloys which exhibit unusual ability to form glass. These materials can be cast as monolithic glass samples. They carry out research on the glass forming liquids. Studies of viscosity, flow, atomic diffusion, surface tension, and crystal nucleation in the undercooled melt are performed. Fundamental studies of the glass transition and thermal properties of the liquid and glassy state are done.

Characterization techniques employed include x-ray diffraction and small angle x-ray scattering, neutron scattering (in collaboration with IPNS, at Argonne Nat. Lab), field ion microscopy, high resolution TEM, thermal analysis and calorimetry, and containerless processing by electromagnetic and electrostatic levitation of liquids. They participate in flight experiments on liquid alloys aboard the IML-2 and MSL-1 flights of the space shuttle.

The mechanical properties of the monolithic glasses are under investigation. These include measurements of strength, ductility, toughness, and quasi static and dynamic deformation behavior. Collaborative research with faculty in the Applied Mechanics option (e.g. Prof. A.J. Rosakis) is part of this work. Studies of deformation and failure as a function of strain rate are done using high speed imaging and temperature measurement methods. Metallic glass matrix composites have been synthesized in which ceramic reinforcement or ductile metal reinforcement is used to strengthen, toughen, and otherwise improve the engineering properties of metallic glasses. The work includes studies of impact, fatigue, and other important engineering properties of the composites.

Development of casting and processing methods for producing near net shape components of metallic glass is performed. Methods for synthesis of composite materials are explored. This program has a strong emphasis on applications and technology transfer.

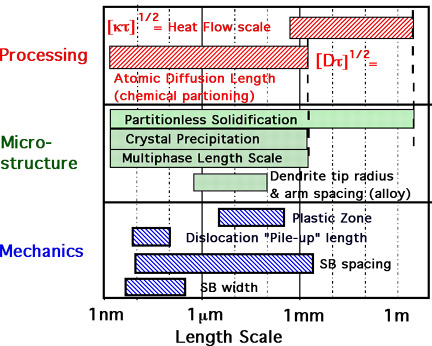

Some length scales for physical phenomena in the structure, processing and properties of materials.