Mossbauer Diffraction from Polycrystalline 57Fe

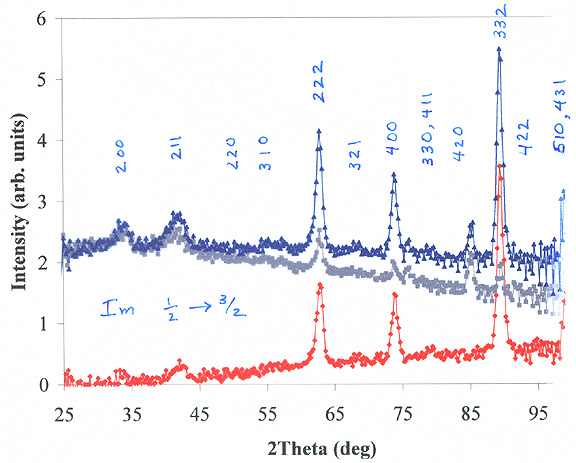

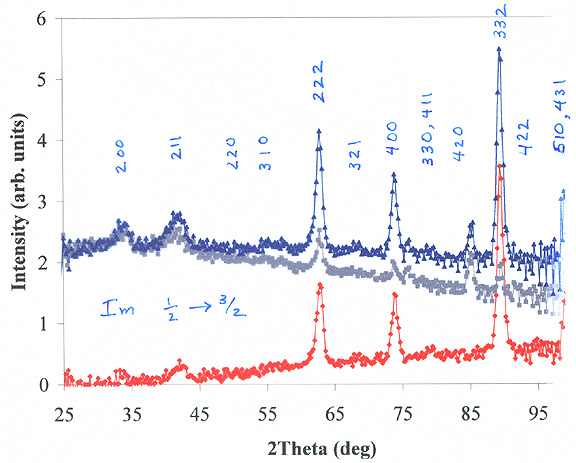

Notice how the red curve has a smooth background from conventional incoherent Mossbauer scattering. We expect that a conventional Mossbauer spectrum would be obtained from this broad and smooth background. The red curve also shows excellent diffraction peaks, especially at the higher angles. The signal-to-noise of these diffraction patterns is unprecedented for polycrystalline materials. Suddenly it seems that Mossbauer powder diffraction is a viable experimental technique for the characterization of structure of materials enriched in 57Fe.

Mossbauer diffractometry offers a unique chemical selectivity, because it can combine the spectral information of Mossbauer spectrometry with the structural information of diffraction. In a recent study [T. A. Stephens and B. Fultz, "Chemical environment selectivity in Mössbauer diffraction from 57Fe3Al", Phys. Rev. Lett. 78, 366 (1997)], we showed that Mössbauer diffraction can be used to measure different autocorrelation functions for 57Fe atoms in different chemical environments. The sample was polycrystalline 57Fe3Al with the ordered D03 structure. Diffraction peaks from an fcc structure with a doubled unit cell were detected when the incident radiation was tuned to the Mössbauer resonance of the Wyckoff 4(b) Fe site, but not for tuning to the 8(c) site, thereby distinguishing the spatial arrangements of these two Fe sites.

The improvement in signal-to-noise ratio with the new diffractometer is at least a factor of 100 better than the system used to obtain the results published in 1997.